Spray Foam Insulation Rigs Full Description

Spray Foam Insulation Rigs: Efficient and Professional Mobile Foam Spraying Workstations

Spray Foam Insulation Rigs are efficient, professional, and fully mobile foam spraying workstations. They integrate multiple core components onto a truck or trailer, allowing for the spraying of open cell or closed cell polyurethane (PU) and polyurea materials. These rigs are highly flexible, offer excellent work efficiency, and can quickly perform foam filling, insulation, waterproofing, and concrete lifting. A complete Spray Foam Insulation Rig typically includes a spray foam machine, generator, air compressor, material tanks, spray hoses, and essential safety equipment.

500w,https://cdn.xinlingmachine.com/uploads/medium_image_c5efb78434.png 750w,https://cdn.xinlingmachine.com/uploads/large_image_c5efb78434.png 1000w," sizes="100vw" width="1396" height="660">

500w,https://cdn.xinlingmachine.com/uploads/medium_image_c5efb78434.png 750w,https://cdn.xinlingmachine.com/uploads/large_image_c5efb78434.png 1000w," sizes="100vw" width="1396" height="660">

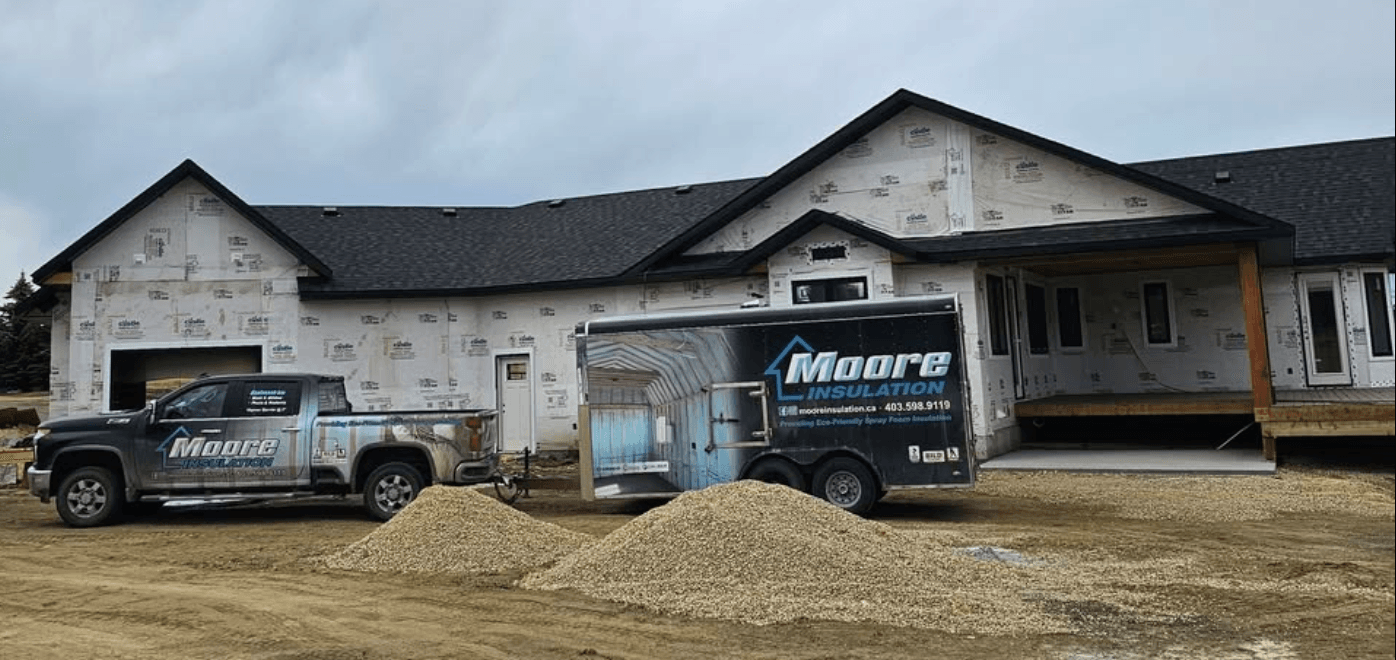

Spray Foam Trucks and Trailers

The truck or trailer is the carrier of the mobile spray foam rig, integrating all equipment into one convenient and flexible unit. It can be driven directly to the job site to provide on-site foam spraying services. The minimum length of a spray foam truck is usually 6 meters, while larger rigs equipped with machines like the E-xp2 or FD-FD-511-pro" class="text-primary hover:text-primary-dark underline transition-colors" title="Dual‑gun Hydraulic Polyurea Sprayer FD‑511‑PRO" data-type="product" data-similarity="1.00">511 may exceed 9 meters. Prices vary widely: a standard trailer can cost around $1,000, whereas used trucks from China typically cost about $10,000.

Spray Foam Machines

The spray foam machine is the core of the system. It uses a material pump to feed raw materials into the main unit for preheating and heating. The heated materials are then delivered by a proportioning pump to a heated hose and finally sprayed through AP or P2 spray guns, producing atomized polyurethane or polyurea foam.

Prices for spray foam machines vary significantly. Top brands like Graco and PMC range from $50,000 to $100,000, while second-tier brands such as Pusmak range from $20,000 to $60,000. The main factors affecting price are brand reputation and system stability. Chinese spray foam machines offer a strong cost-performance advantage. For example, the FD-FD-511-pro" class="text-primary hover:text-primary-dark underline transition-colors" title="Dual‑gun Hydraulic Polyurea Sprayer FD‑511‑PRO" data-type="product" data-similarity="1.00">511 can match the capabilities of the Reactor2 H-xp2 but costs under $8,000, providing stable pressure, excellent atomization, and built-in warning and protection systems. E-series machines, such as the E30, can be purchased for less than $5,000.

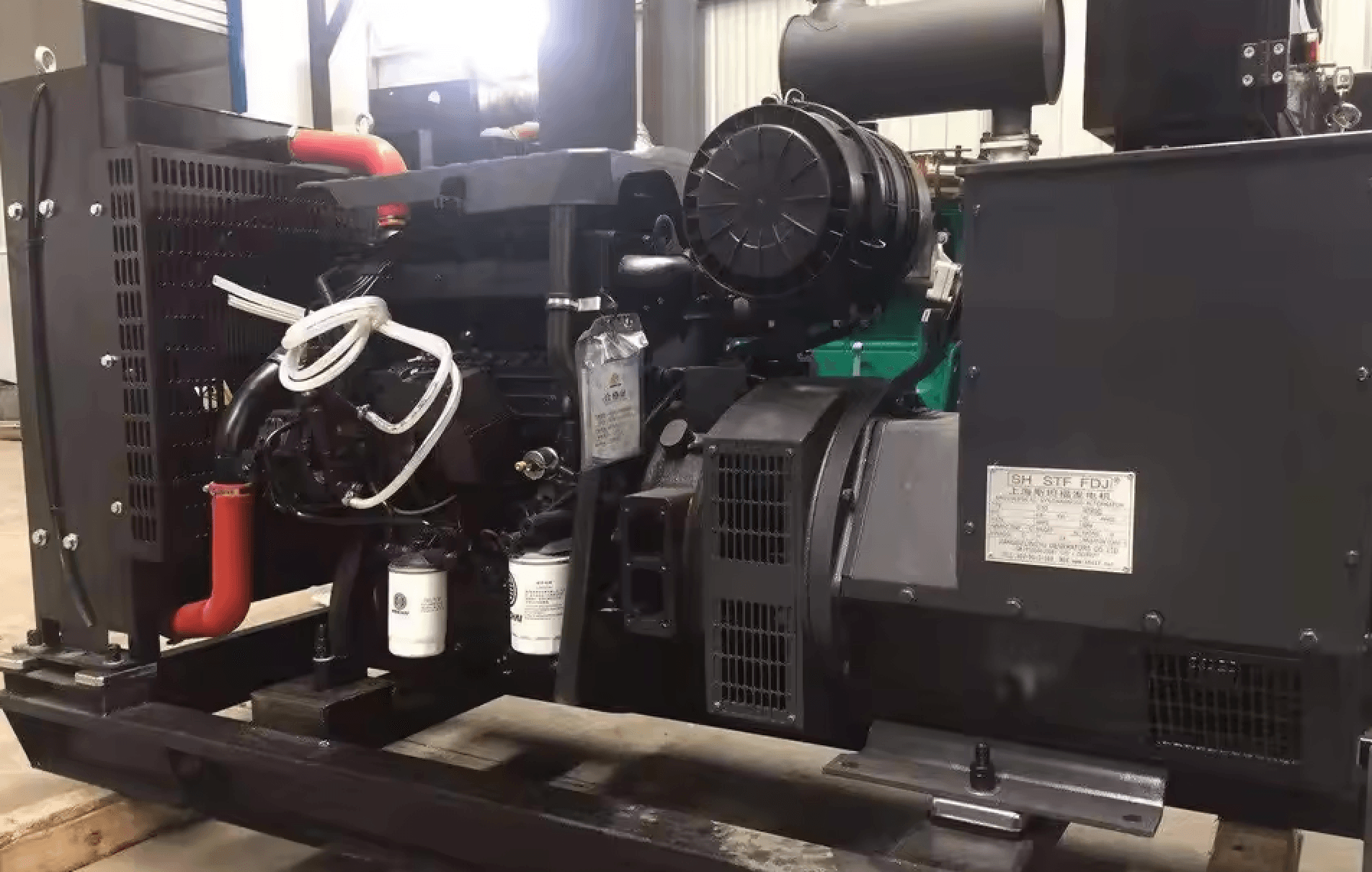

Generators

Generators provide power for the spray foam machine and air compressor. Typical foam spraying machines require around 22 kW, and hydraulic machines need only a 2.2 kW air compressor. A 30–35 kW diesel generator is usually sufficient, with dimensions around 900 × 850 × 1250 mm. Chinese-made generators are cost-effective, priced at approximately $1,700.

500w, https://cdn.xinlingmachine.com/uploads/medium_image_da4f52576a.png 750w, https://cdn.xinlingmachine.com/uploads/large_image_da4f52576a.png 1000w" sizes="100vw" width="1000">

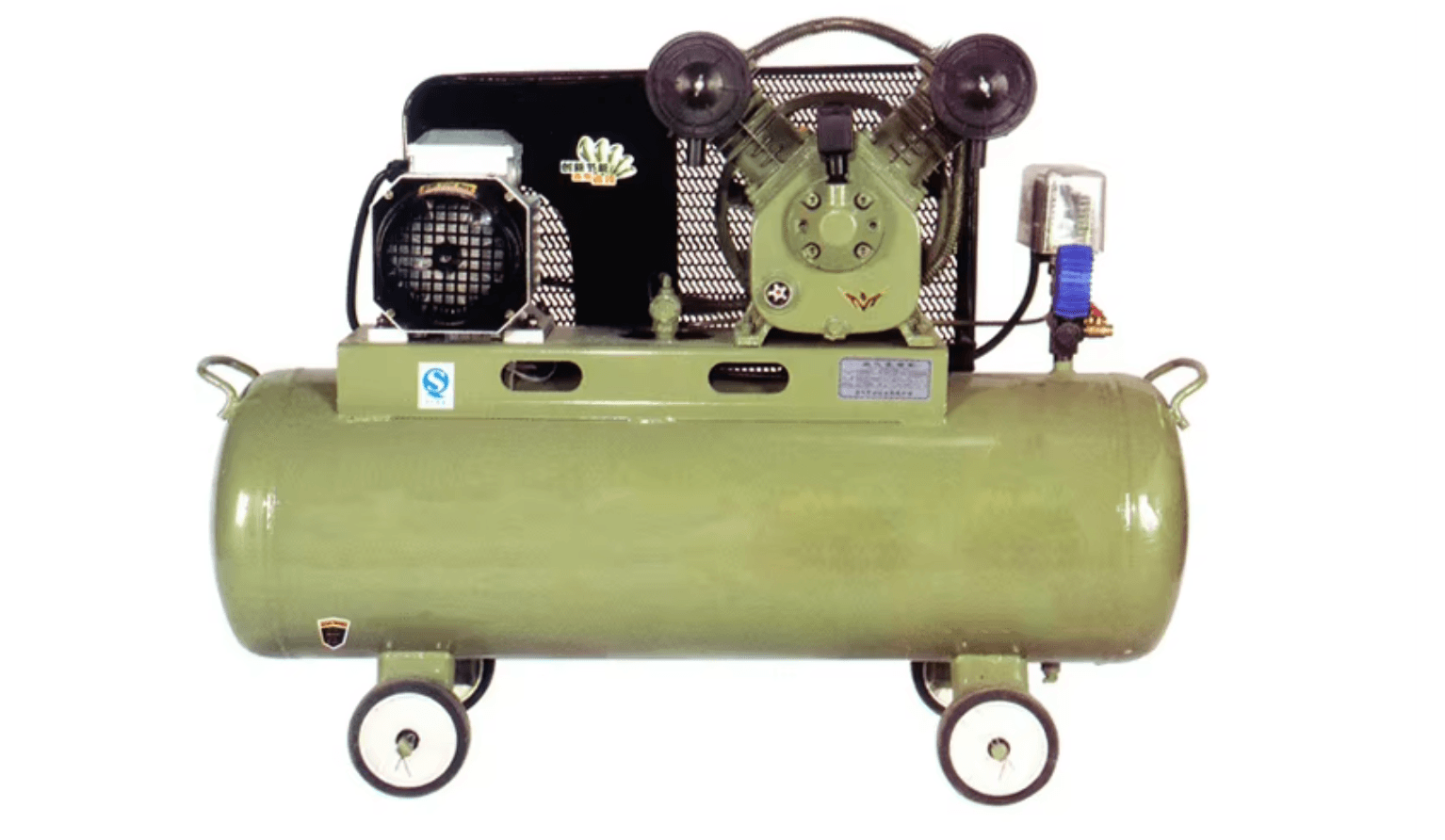

500w, https://cdn.xinlingmachine.com/uploads/medium_image_da4f52576a.png 750w, https://cdn.xinlingmachine.com/uploads/large_image_da4f52576a.png 1000w" sizes="100vw" width="1000">Air Compressors

Air compressors supply power to the material pump and spray guns. Piston-type compressors are reliable and durable, compact in size (about 1050 × 420 × 800 mm), and affordable. Small Chinese-made piston compressors typically cost around $360.

Spare Parts and Accessories

To keep the system running smoothly, spare parts such as spray guns, hoses, and material pumps are necessary. Prices for individual components are roughly: material pump $420, AP spray gun $900, and 15-meter heated hose $400. Most main units come with standard accessories included.

Additional accessories include foam trimming tools for open or closed cell foam and essential safety equipment like fire extinguishers and protective clothing, which are relatively inexpensive.

500w, https://cdn.xinlingmachine.com/uploads/medium_image_9a1c593d7c.png 750w, https://cdn.xinlingmachine.com/uploads/large_image_9a1c593d7c.png 1000w" sizes="100vw" width="1000">

500w, https://cdn.xinlingmachine.com/uploads/medium_image_9a1c593d7c.png 750w, https://cdn.xinlingmachine.com/uploads/large_image_9a1c593d7c.png 1000w" sizes="100vw" width="1000">By reviewing the above, you can clearly understand the components and investment required to set up a complete Spray Foam Insulation Rig. For approximately $8,500, you can assemble your own mobile spray foam rig and perform multiple construction tasks including insulation, waterproofing, foam filling, and concrete lifting.

Efficient, flexible, and cost-effective — the perfect starting point for entering the spray foam industry!