Spray Foam Hoses

spray foam heated hoses are designed specifically for use with Reactor Equipment. Hoses are a key component to the total system, making it important to achieve accurate and uniform heating for the best application possible

Product Details

Important attributes

Heated Hose 3/8", 3500 PSI, RTD, 50 ft – Compatible with Graco Reactor

This 3/8" heated hose is specially engineered for polyurea and polyurethane spray foam insulation equipment, delivering consistent material temperature for stable mixing and superior spray results. Designed for demanding insulation, sealing, waterproofing, and coating applications, this hose combines advanced heating, insulation, and durability technologies to ensure reliable performance in any environment.

Key Features

High-Efficiency Heating System

The Graco-compatible heated hose offers two heating configurations: internal heating (20V–24V) and external heating (12V–16V).

Internal heating ensures faster and more uniform temperature transfer.

External heating allows easy maintenance and replacement.

This flexibility makes the hose ideal for different spraying systems and construction site needs.

RTD Precision Temperature Control

Built-in high-sensitivity RTD (Resistance Temperature Detector) continuously monitors and regulates the hose temperature, maintaining an ideal spraying temperature even under changing environmental conditions. This prevents overheating, cold spots, or material curing issues, ensuring a perfect mix every time.

Superior Durability and Flexibility

Made from high-strength flexible materials, the hose offers excellent abrasion resistance, anti-aging performance, and long service life. It remains flexible even under frequent bending, allowing smooth operation and easy handling during construction.

Fully Compatible with Graco Equipment

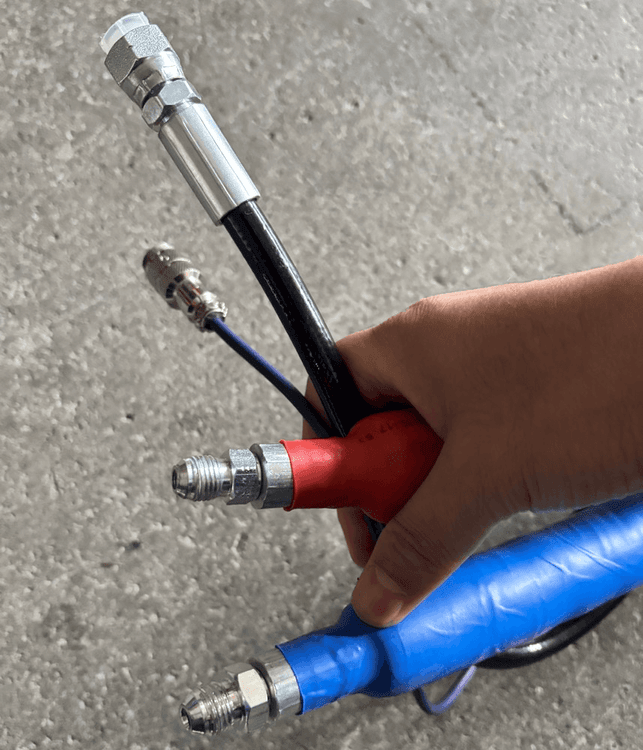

The hose’s interface size matches Graco Reactor systems perfectly and supports JIC5 and JIC6 connectors, allowing direct installation without additional modifications.

It’s easy to operate, quick to assemble, and simple to maintain—ideal for both new installations and replacement applications.

Technical Advantages

Multi-strand copper heating element provides 10× longer flex life compared to traditional flat copper heating wires.

Ensures even heat distribution with no localized hot spots.

High-quality electrical components enable rapid heating response and precise temperature feedback.

Advanced insulation design delivers fast heating, uniform heat conduction, and stable temperature control.

Resin-reinforced hose structure increases internal strength while maintaining excellent flexibility and lighter handling.

Butyl protective cover resists moisture-sensitive isocyanates and protects internal heating elements.

Foam insulation layer helps retain heat for maximum energy efficiency.

Color-coded fittings and custom splice kits prevent incorrect hose connections between A (iso) and B (resin) materials.

Applications

This high-performance heated hose is widely used in industrial and construction fields, including:

Polyurea waterproofing and coating projects

Polyurethane foam insulation spraying

Pipeline anti-corrosion coating

Roof and floor protection

Tank, bridge, and large structural spraying applications

Specifications

Inner Diameter: 3/8 inch

Length: 50 ft (15.2 m)

Working Pressure: 3500 PSI

Heating Type: Internal/External (optional)

Temperature Sensor: RTD (Resistance Temperature Detector)

Compatibility: Graco Reactor Series, JIC5 / JIC6 Connectors

Supplier Info

Jinan Xinling Intelligent Technology Co.,Ltd

Professional Spraying Equipment Manufacturer

Contact Information

- 8618311346723

- sales@xinlingmachine.com

- Gaoxin District, Jinan City, Shandong Province (No. 188 Chunbo Road)