Hydraulic spray foam machine

Working Principle of Spray Foam Machine

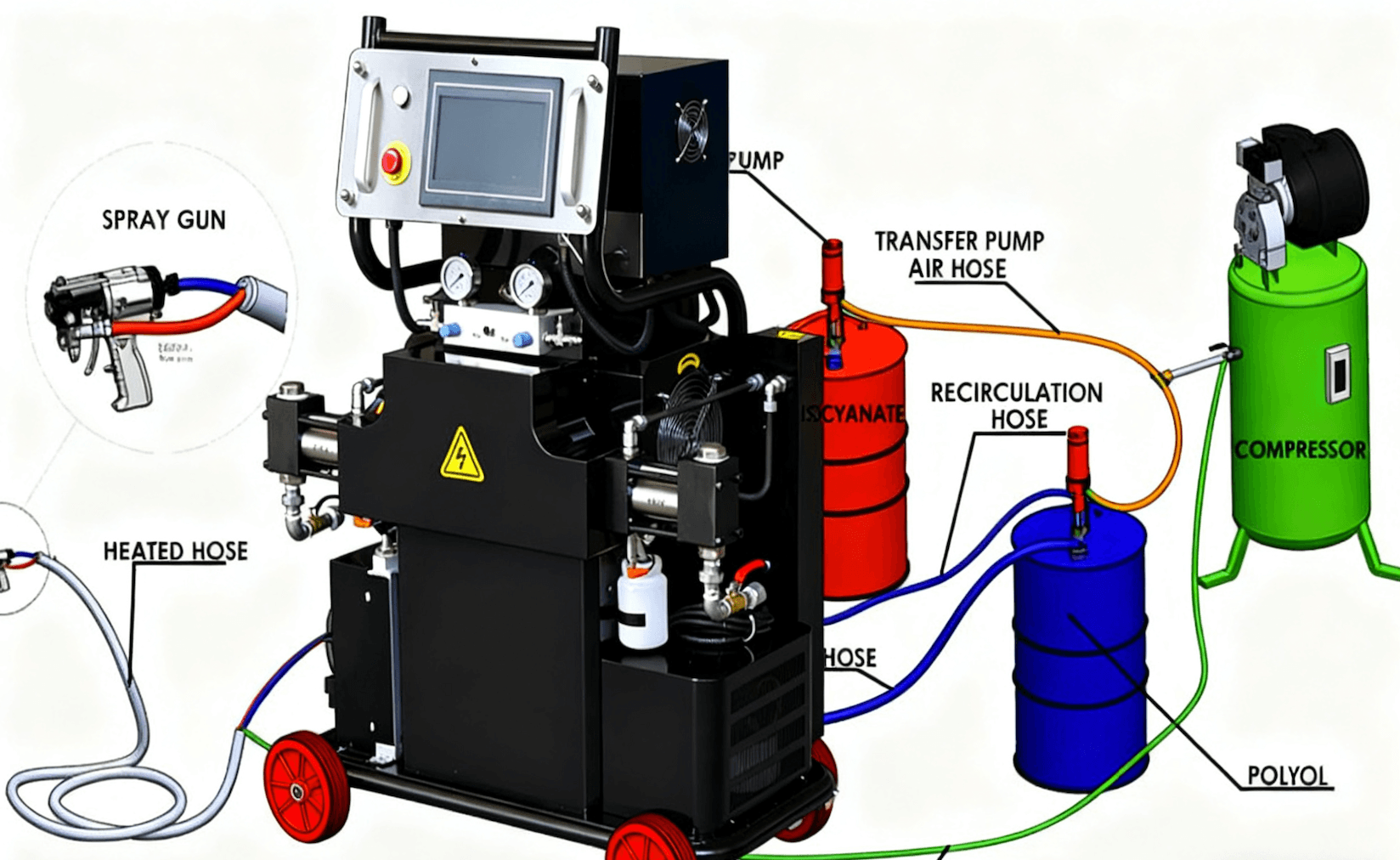

Spray foam machines (also called polyurethane spray foam machines or spray foam insulation machines) usually consist of two independent transfer pumps and a pressure pump, capable of independently heating hoses and achieving precise mixing and proportioning. Therefore, they are also referred to as spray foam reactors.

A foam spraying machine is a professional polyurethane/polyurea spraying equipment. The working process is as follows:

First, two liquid chemical components—isocyanate (Component A) and polyol resin (Component B)—are delivered to the machine via transfer pumps and heated to 40°C–70°C by the heating system. Then, the two components are pressurized to 150–250 bar using high-pressure piston pumps and delivered to the spray gun through heated hoses at an accurate 1:1 ratio. In the mixing chamber or static mixer of the spray gun, Component A and B collide under high pressure and instantly form a uniform reactive liquid.

When the mixed liquid is sprayed onto the substrate, a chemical reaction occurs immediately, atomizing the material and forming a dense and solid polyurethane foam layer within approximately 30 seconds.

How to Use the Spray Foam Machine

A complete spray foam system typically includes: a spray foam reactor, air compressor, two transfer pumps, two heated hoses, and a mixing spray gun. The spray gun is where the chemical reaction takes place, while the air compressor provides the air source for pump operation and gun cleaning. Operating Steps:

Equipment Connection: Connect all components, then start the air compressor and the spray foam reactor.

Preheating: Connect the recirculation lines to the A and B material drums. Open the return valves and close the hose valves to allow material to circulate and heat. Once the temperature reaches 40–60°C, spraying can begin.

Air Purge and Pressurization: Purge air from the system to ensure the lines are filled with material. Gradually increase pressure to the preset level before spraying.

Spray Test: Perform a test spray on waste board to verify mixing ratio, curing speed, and coating quality. Hold the spray gun perpendicular to the surface at a distance of 50–70 cm, moving at a speed of 0.5–1 m/s.

Transfer Pumps:

Pumps A and B: All spray foam sprayers, including polyurea sprayers, have a vertical or horizontal pump: one pump for component A and one pump for component B.

Pressure Gauges

All spray foam machines and polyurea machines have analog liquid pressure gauges.

Found on polyurethane spray machines and polyurea machines, these analog fluid pressure gauges allow the contractor to monitor material flow for even stability.

These analog liquid pressure gauges are also important for troubleshooting equipment malfunctions in Spray foam machines and polyurea machines.

Extreme Pressure Sensors

In spray foam machines and polyurea machines, overpressure sensors are used in case of accidental overpressurization of the proportioner.

The sensors are preset by the manufacturer to prevent the proportioner from being exposed to excessive pressure.

Overheat Sensors

Overheat sensors are used in case the controller in spray foam machines and polyurea machines accidentally overheats from the set point.

How We Ensure Stable Operation

Since the spray foam machine operates under high temperature and pressure, multiple intelligent safety protection systems are integrated to ensure stable and safe performance:

- HOSE Overheat: Automatically stops heating and triggers alarm if hose temperature exceeds limit to prevent damage.

- ISO / POLY Overheat: Monitors A/B material temperature in real time; cuts off power when exceeding range to prevent crystallization or abnormal reaction.

- Pressure Difference Too Large: Triggers alarm and stops operation when pressure difference between A and B sides is excessive, preventing ratio imbalance or clogging.

- Barrel Empty: Smart level detection warns when material is low to prevent air from entering the system.

- Temperature Sensor Disconnect: Monitors sensor status and stops heating if any sensor is disconnected or malfunctioning.

How Spray Foam Machines Ensure Accurate Mixing Ratio

- Proportioning Pump System: Each material has an independent hydraulic proportioning pump with fixed displacement, ensuring precise 1:1 ratio output.

- Pressure Control System: Built-in sensors monitor both sides’ pressure in real time, automatically compensating for flow deviation.

- Digital Control System: Displays real-time parameters such as pressure, temperature, and flow rate; automatically shuts down in case of abnormal conditions; supports data storage and fault diagnostics.

- High-Precision Mixing Spray Guns: AP and P2 series guns feature an air-purge mixing chamber design for even mixing and reduced clogging.

Accuracy of Temperature Control

- PID temperature control system with independent 3000W–8000W heating modules for A/B sides. Each side can be individually adjusted and quickly heated to 35–70°C with ±2°C accuracy.

- Recirculation heating system ensures uniform overall temperature.

- Heated hoses use internal heating design with RTD temperature sensors for precise thermal control.

Safety Measures

Our spray foam machines are equipped with dual pressure and temperature protection systems, automatic alarm and shutdown, overload and leakage protection, emergency stop button, and explosion-proof electrical control system — providing full-spectrum safety during operation.

Product Quality Assurance

- Over 18 years of technical expertise, with an annual output of over 1,000 units.

- Core components use world-class brands: Buttons & controllers (Siemens), Electrical components (Schneider), Hydraulic pumps (Japan), Solenoid valves (Italy), O-rings (USA).

- Each unit undergoes multiple tests for performance, sealing, and electrical safety before shipment — ensuring stability under high pressure, high temperature, and continuous operation.

- Comes with 2-year warranty and one set of sealing parts; free seal replacements even after warranty period.

FAQ

1. How Many Volt Power Supply Is Required?

Standard units require 220V single-phase or three-phase power. Small electric models can support 110V single-phase, and custom voltages are available.

2. Does Heater Size and Power Vary ?

Yes. By adjusting the heated Hose transformer level, hose length can be matched as needed. Standard units support 60 meters; larger models up to 120 meters.

3.Can Hose Temperature Be Controlled in Spray Foam Machines? Temperature sensing units: On sprayers and polyurea machines (TSU), and the Fluid Temperature Sensor (FTS), it is usually aligned with the heated spray hose and is used to sense the hose temperature.

4. What is the Position of Components A and B?

Yes. Default configuration: A (isocyanate) on the left, B (polyol) on the right — adjustable based on user habit.

5. What Do Y-Strainers Do ?

Y-Strainers out impurities from raw materials to protect the system; mesh size adjustable and easy to clean or replace.

6. What Are the Common Wear Parts?

Includes PTFE tape, proportioning pump seals, combined gaskets, air fittings, thermal protectors, and O-rings — should be checked and replaced regularly.

7. Routine Maintenance

- Clean all hoses and guns after each job;

- Replace filters monthly;

- Replace seals and lubricate moving parts every 500 working hours.

8. Can Extra Heating Blocks Be Added for Cold Regions?

Yes. An additional 2kW heating module can be installed to enhance heating and insulation.

9. Is There a Security Key?

Equipped with cycle counter and safety stop switch for higher operational safety.

10. How to Prevent A-Side Crystallization?

The A-side is sensitive to moisture. Our system includes a DOP cleaning system, which uses DOP oil to flush the circuit, preventing crystallization and clogging.

11. Can the Machine Operate Continuously?

Equipped with a large-capacity hydraulic oil cooling system, the machine can run continuously for 24 hours.

12. Machine Running But Hydraulic Pressure Shows Zero?

Indicates air in the system. Activate recirculation to vent air; if pressure difference alarm occurs, clean the mixing chamber and filters.

14. Common Troubleshooting

- Foam Blistering: Check for moisture in materials or uneven mixing; increase pressure or clean mixing chamber.

- Gun Clogging: Clean the nozzle with solvent—avoid using sharp tools.

- Pressure Fluctuation: Check for leakage or worn pump valves; replace parts as needed.