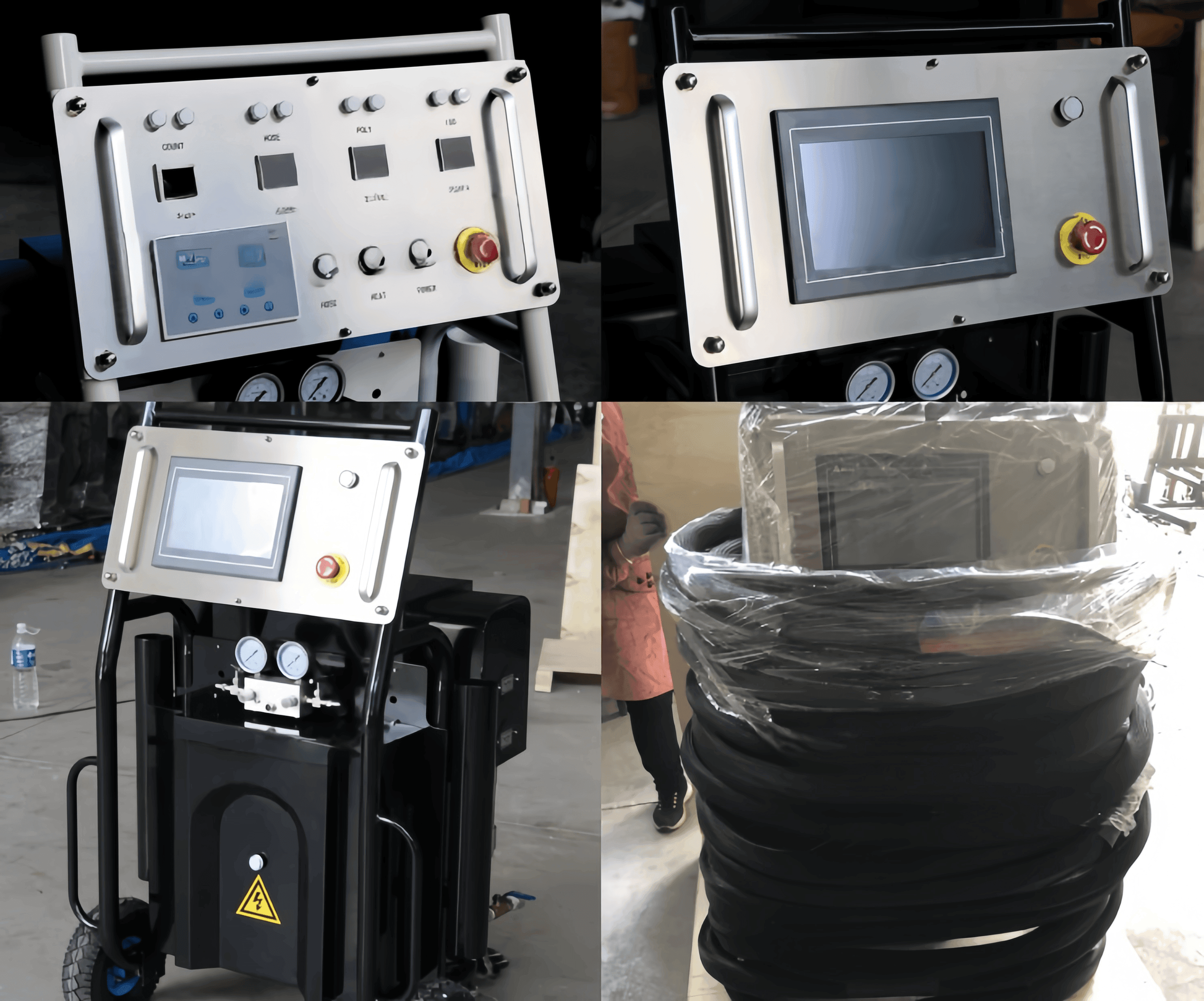

High Power Electric Polyurethane Sprayer FD-2E

High-power electric polyurethane/polyurea spraying machine that can replace hydraulic equipment flatly and can also be dosed. High power, compact and flexible

Product Details

Important attributes

standard configuration

Electric Polyurethane/Polyurea Sprayer FD-2E

FD-2E Electric Polyurea Spray Foam Insulation Machine is a cost-effective two-component spraying equipment benchmarked against Graco Reactor E-XP2 Elite Level Proportioning System, specially designed for the accurate spraying of fast-curing materials such as polyurea and polyurethane. Adopting electric drive to replace the traditional hydraulic system, on the basis of the continuation of the core proportioning technology of E-XP2, with 23MPa high pressure output, 120 meters of extra-long hose adaptation and 12kg/min large flow rate performance as the core advantage, to strengthen the adaptability of medium and large-scale projects and construction flexibility, and to become the preferred equipment for the scenarios of long-distance pipeline anticorrosion, waterproof and heat preservation of a large area, and other scenarios.

- Two-component accurate proportioning: Equipped with the same gear metering technology as E-XP2, the error of A/B material proportioning is ≤±1%, combined with the constant high pressure output of 23MPa, to ensure that the high-viscosity materials are fully mixed, and to solve the problem of cracking of the coating due to the deviation of the ratio of the polyurea spraying.

- Super flow rate output: 12kg/min (27lb/min) flow rate is 60% higher than the basic model, shortening the working time by 40%.

- Intelligent pressure balancing: upgraded pressure balancing valve and real-time sensing system automatically adjusts the output pressure when it fluctuates ±0.5MPa, avoiding the problem of pressure decay in the 120-meter long-distance conveying.

- Intelligent large screen: adopting 10-inch operation screen, easy to operate.

- 120 meters hose conveying system: adopts high pressure resistant heating hose (1000W/15m segmented design), through the end temperature detection, the fluid temperature at the end of 120 meters still maintains above 85℃, which is suitable for long-distance pipeline, large tanks and other scenarios of long-distance construction.

- Wide temperature control: 88℃ (190℉) precise temperature control combined with 4500W independent heaters on both sides, supporting A/B material temperature difference compensation, even at a low temperature of 5℃, the coating can realize the fast curing effect of 5 seconds of gel and 1 minute of walking strength.

- Multi-voltage adaptive: three-phase 230V/440V dual-voltage design, with a wide frequency power supply module, suitable for domestic and international industrial power grids, field construction can be used with 15kW generator stable operation.

- High-efficiency and energy-saving structure: the 12kW power of the whole machine saves 25% of electricity compared with hydraulic models with the same flow rate, and the 120-meter heated hose adopts intelligent temperature control, which automatically reduces to the heat preservation mode when it is not in operation section and saves about 8 yuan of electricity cost per hour.

- Easy maintenance system: Drawing on the E-XP2 quick-disassembly design, the pump cylinder liner can be replaced within 10 minutes, and the seals are made of solvent-resistant fluoroelastomer, which extends the service life to more than 800 hours; the 120-meter hose supports disassembly and cleaning in sections to avoid clogging of material residues.

- Safety protection: Equipped with double protection of automatic shutdown when the material is exhausted and power failure when the heating system is over-temperature (≤90℃); 120 meters of hose with built-in ground wire and leakage detection, the construction safety coefficient is in accordance with IEC 61010 standard.

Pipeline internal and external wall anti-corrosion: 120 meters of hose is suitable for Φ50-1500mm diameter pipeline, 23MPa high pressure to ensure uniform adhesion of the coating, thickness deviation ≤ ± 0.2mm, salt spray test corrosion resistance of more than 5,000 hours; support for overhead pipelines, buried pipelines continuous spraying, no need to move the equipment frequently.

Large roof waterproofing: 12kg/min high flow with double spray gun operation, single day can complete 1500 square meters of roof polyurea spraying, -5 ℃ low temperature environment, normal construction, coating tensile strength ≥ 18MPa, suitable for factories, warehouses and other large areas of waterproofing needs.

Cold storage and cold chain facilities: 88 ℃ accurate temperature control to ensure that the polyurethane foam layer closed cell rate ≥ 92%, 120 meters of hose can cover the three-dimensional wall spraying of large-scale cold storage; for the cold chain containers, dosing error ≤ ± 20g, to meet the needs of fine thermal insulation.

Industrial facilities protection: 23MPa high pressure adaptable wear-resistant polyurea material for waste water treatment tanks, chemical reactor lining spraying, coating acid and alkali corrosion (pH value 2-12), 12kg/min flow rate to ensure that the 10mm-thick coating molding, service life of more than 15 years.

Anti-corrosion of bridges and steel structures: dual-voltage adaptable to field construction, 120m hose can cover all-round spraying of steel box girders and steel members of bridges, with tungsten carbide nozzles, the coating adhesion reaches more than 5MPa, and the anti-impact strength is 15kJ/m².

Maintenance of energy facilities: suitable for wind power towers, oil storage tanks anti-corrosion, 12kg/min high flow rate to shorten the construction cycle, 23MPa pressure to ensure that the high viscosity anti-corrosion coating fully atomized, coating uniformity better than the industry standard.

Supplier Info

Jinan Xinling Intelligent Technology Co.,Ltd

Professional Spraying Equipment Manufacturer

Contact Information

- 8618311346723

- sales@xinlingmachine.com

- Gaoxin District, Jinan City, Shandong Province (No. 188 Chunbo Road)