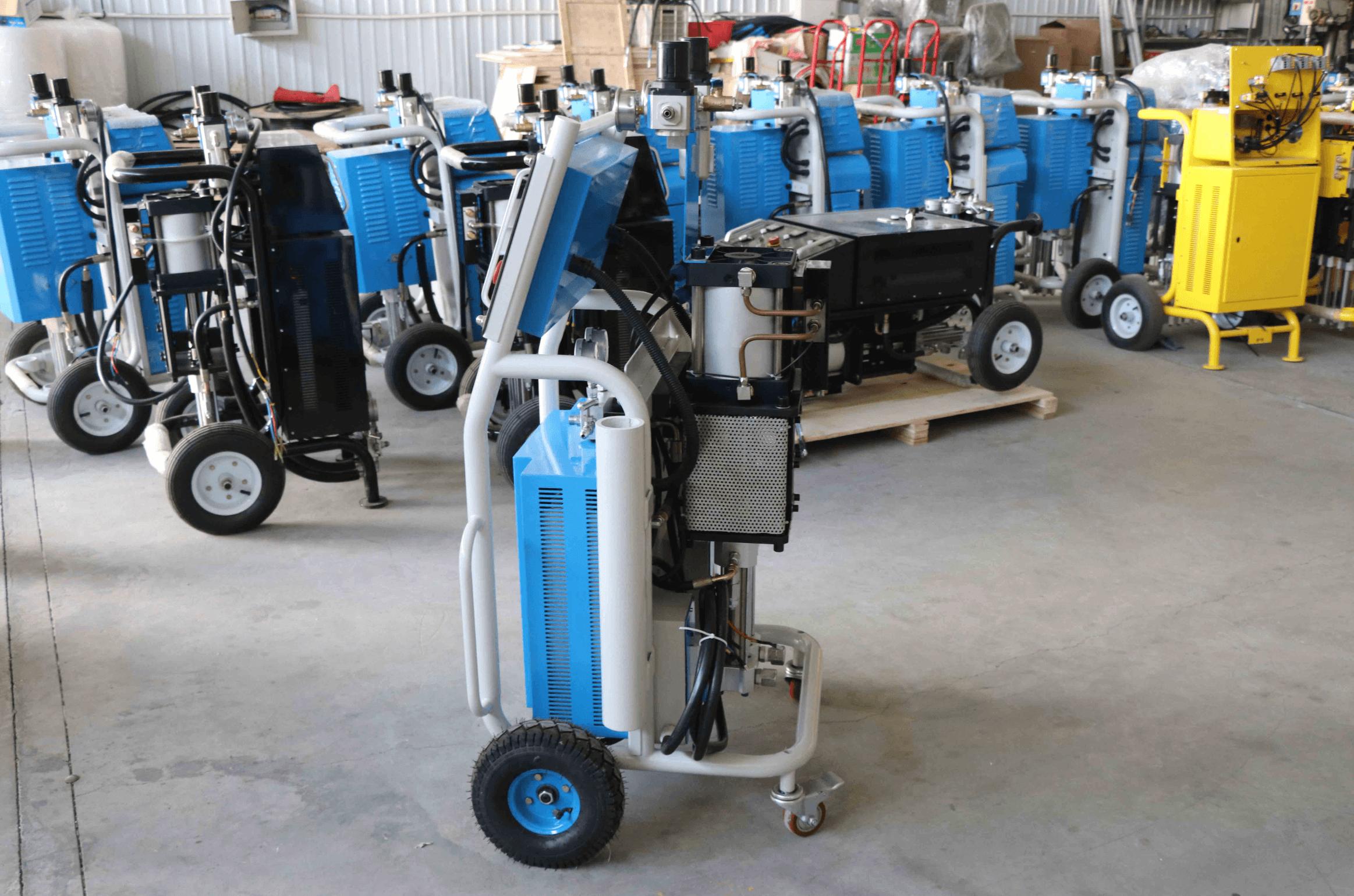

Pneumatic Foam/Sprayer FD-411A

Heart-saving and durable pneumatic polyurethane spraying machine, injection foaming machine, using the international first-line accessories, can realize quantitative filling

Product Details

Important attributes

standard configuration

Polyurethane Spraying / Injection Foaming Machine FD-411A

As a leading product in the field of polyurethane spraying machine, FD-411A relies on more than 18 years of high-end original independent design experience, insists on adopting imported original configurations, rejects low-end materials, and wins the market's recognition with stable and reliable product quality. Its core configuration, the FD-411B pneumatic drive proportional unit, adopts an advanced and compact design, specially designed for polyurethane foam application scenarios. The special structural configuration makes all components easy to access, dramatically simplifying the control process and significantly reducing maintenance workload.

Core system advantages

- Heating system: consists of two independent heating blocks, which are heated quickly and separately to the target temperature, ensuring efficient and precise material heating.

- Proportional pumps: Equipped with two positive displacement piston pumps driven by pneumatic motors to ensure stable and uniform material transfer.

- Hose Heating System: Heating hose power up to 1000W per 15 meters, supporting the heating needs of up to 90 meters, to meet the temperature requirements of different operating ranges.

- Recirculation system: Before the start of spraying and during temporary shutdown, the two components can be recirculated to help the heater reach the preset temperature faster and improve the efficiency of work preparation.

Core Upgrade Highlights

- Adoption of enlarged cylinder design effectively improves spraying mixing uniformity and guarantees stable coating quality.

- Electronic components and seals are selected from imported brands to ensure stability in long-term use and reduce breakage and other failures, sticking to high-end quality positioning and rejecting low-end distribution.

- The heated hose is equipped with voltage protection function, which guarantees the safety of electricity from the source and reduces the risk of operation.

- Guns and heated hoses can be used with GRACO brands, increasing equipment compatibility and accessory replacement flexibility.

- Accurately maintains temperature setpoints to minimize changes in material properties due to temperature fluctuations, helping to improve product yield and quality.

- Maintains stable output pressure to ensure uniform spray patterns for consistent spraying results.

- Simple and convenient operation and maintenance process, reducing the threshold of manual operation and post maintenance costs.

- Equipped with a resettable counter to accurately track material usage for easy cost accounting and material management.

- Three independent heating zones - for ISO, resin and hose - for targeted temperature control.

- Digital temperature control system provides precise heat control based on the viscosity of different chemicals for reliable application.

- Enables quantitative filling

Can be applied to the following scenarios:

1. Polyurethane spraying on walls and roofs, polyurea spraying for waterproofing and corrosion prevention

2. Caulking of construction joints, spray insulation of cold rooms, spray insulation of tanks and pipes

3. Polyurethane foam for packaging cushioning, spray insulation for car roofs

4. Insulation filling

Supplier Info

Jinan Xinling Intelligent Technology Co.,Ltd

Professional Spraying Equipment Manufacturer

Contact Information

- 8618311346723

- sales@xinlingmachine.com

- Gaoxin District, Jinan City, Shandong Province (No. 188 Chunbo Road)